Jinan bakr Ultrasonic Technology Co., Ltd. Is a High-tech enterprise specialized in R&D, manufacture and sales of Industrial cleaning equipments.The headquarters located in Lingang Development Zone of Jinan,owns over 13,000 square meters standardized workshop area and a total registered capital of RMB

8,000,000($ 1273, 885).Sinobakr owns employees number of 120 people, include 30 engineers, 10 new project R&D technicians, and 10 professional after-sales engineers.

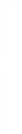

Our company mainly produces Semi-automatic,Fully automatic ultrasonic cleaning line, Automatic vapor cleaner, Hydrocarbon cleaning and drying equipment.We elaborately develop all kinds of middle-high pressure spray cleaning equipments ,such as Continuous through type, Rotary through type, Hanging through type,Reciprocating,Liftig type, Lifting and stepping conveyor etc. as well as the deburring equipments, which have the advantages of novel structure, fully functions, high reliability, convenient operation and maintenance, will completely take the place of the imported equipments.

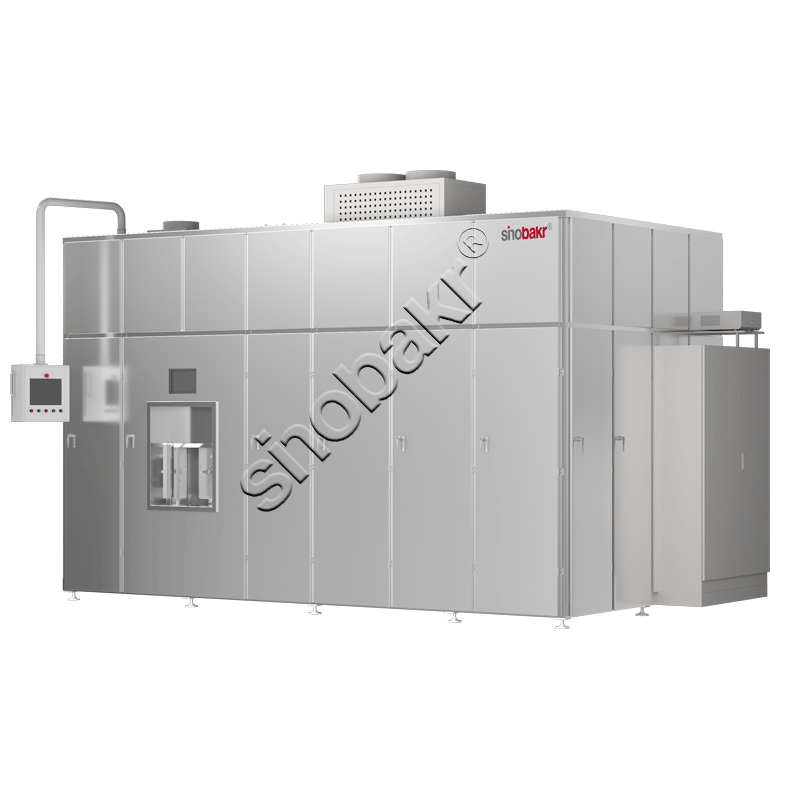

Our products are widely used in the industries as automobiles, locomotives, construction machinery,internal combustion engines, aircraft, aerospace, medical, electroplating, pharmaceuticals, new material,precision electronics, optical lenses, pneumatic and hydraulic machinery, solar photovoltaic and mobilephone and many other fields.

In 2008,the company passed the ISO9001 Quality management system certification and CE certification.Till now, Sinobakr products have been exported to Europe, Australia, Asia,North and SouthAmerica, Africa,etc.totally to more than thirty countries and areas. Good quality and well services have gained Sinobakr very good reputation and well popularity in the world.

Customer service

Customer service