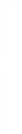

Modified simplex bit alcohol equipment advantages

1. The equipment structure is compact, small footprint, vacuum sealed tank cleaning, the cleaning process in a state of vacuum protection.

2. The modified alcohol solvent cleaning machine the processing system of operation is under the condition of vacuum (< 100 mbar) to ensure working environment above the flash point solvent

3. After cleaning the parts of high cleanliness, continuous discharge of oil equipment, do not need to wait.

4. Through the heat recovery, the use of solvent steam for heating rinse tank.

5. High and low boiling point substances by fractional distillation boiling point substances, so the solvent quality constant, not affected by the boiling point (effective for hydrocarbons and modified alcohol) and the influence of solvent life.

6. Automatic separation of water and other low boiling point substances, automatic separating mineral oil high boiling point material. Replace filter convenient, automatic emptying, vacuum drying.

7. The built-in vacuum distillation system, the realization of the solvent regeneration recycling/workpiece rapid drying under vacuum.

8. Automatic vacuum cleaning, efficient clean and more thoroughly to ultra precision parts cleaning, energy conservation and environmental protection equipment, in line with national environmental requirements of zero emission, no pollution, high safety level.

9.General cleaning process: ultrasonic cleaning spray cleaning, spray wash sauna ultrasonic cleaning, washing, vacuum drying, each process of the available parameter requirements,Can match up and materials conveying line automatic up-down material, modified alcohol solvent distillation recycling, cover an area of an area small, complete functions, high degree of automation,Can choose a swing or reverse cleaning, energy conservation and environmental protection.

10. Modified alcohol cleaning machine applicable scope

Using water-soluble cutting fluid or mineral oil processing precision parts processing: precision aluminum alloy parts, nozzle, needle valve, piston, powder metallurgy parts, lifter, precision stamping parts, precision valve valve core and aircraft engine components.

Product Application

Package&Delivery

Customer Site

Company Information

Jinan bakr Ultrasonic Technology Co., Ltd. Is a High-tech enterprise specialized in R & D, manufacture and sales of Industrial cleaning equipments. The headquarters located in Lingang Development Zone of Jinan, owns over 13,000 square meters standardized workshop area and a total registered capital of RMB 8,000,000($1273,885).Sinobakr owns employees number of 120 people, include 30 engineers, 10 new project R & D technicians, and 10 professional after-sales engineers.

Our company mainly produces Semi-automatic, Fully automatic ultrasonic cleaning line, Automatic vapor cleaner, Hydrocarbon cleaning and drying equipment.We elaborately develop all kinds of middle-high pressure spray cleaning equipments ,such as Continuous through type, Rotary through type, Hanging through type,Reciprocating,Lifting type, Lifting and stepping conveyor etc. as well as the deburring equipments, which have the advantages of novel structure, fully functions, high reliability, convenient operation and maintenance, will completely take the place of the imported equipments.

Our products are widely used in the industries as automobiles, locomotives, construction machinery, internal combustion engines, aircraft, aerospace, medical, electroplating, pharmaceuticals, new material, precision electronics, optical lenses, pneumatic and hydraulic machinery, solar photovoltaic and mobile phone and many other fields.

In 2008year,the company passed the ISO9001 Quality management system certification and CE certification.Till now, Sinobakr products have been exported to Europe, Australia, Asia,North and South America, Africa,etc.totally to more than thirty countries and areas.Good quality and well services have gained Sinobakr very good reputation and well popularity in the world.

FAQ

1.Does ultrasonic cleaner damage the articles?

Ultrasonic cleaning is considered safe for most parts; although in some cases it is necessary to observe caution, although the effect of thousands of implosions per second is very powerful , the cleaning process is safe.

2.What material do we use for equipment ?

Our equipment such as inner tank, tank body, vibrating plate, basket using excellent sus304 stain steel with long life.

3. How to choose ultrasonic cleaning agent?

There are generally two kinds of ultrasonic cleaning agent, chemical cleaning agent and water-based cleaning agent. Cleaning agent is chemical action while ultrasonic cleaners are physical action. Cleaning objects can be thoroughly cleaned when using both of them. Please choose the right cleaning agent according to different requirements.

4. What are the after-sale services?

1. One year warranty. If any technical problems exist during warranty, replacement will be sent out of charge.

2. Technical support is available forever.

5-1. Does ultrasonic cleaner damage the articles?

Ultrasonic cleaning is considered safe for most parts; although in some cases it is necessary to Observe caution. Although the effect of thousands of implosions per second is very powerful, the Cleaning process is safe.

5-2. How to avoid damaging the work piece during cleaning?

1. To use correct ultrasonic frequency and ultrasonic power.

2. To choose suitable ultrasonic cleaning agent.

3. To choose reasonable tooling basket and cleaning methods

6. What are the advantages of Bakr ultrasonic cleaner over traditional cleaning methods?

1. Minimize the use of manual labor

2. Make cleaning and degreasing without the use of organic solvents.

3. Clean easy to reach areas of products and remove all types of dirt.

4. Shorten the processes such as extraction, dispersion, purification, chemical reactions.

5. Eliminates costly mechanical and chemical cleaning of heat exchangers.

7. What frequency is better for my parts?

Frequency is suggested based on pollutants in the objects.

28kHz frequency is stronger, better for car/motor/truck/vessel parts clean (remove oils, grease, pastes, etc. ) 40kHz is better for PCB boards, electronic parts, etc.

Higher precision goods, higher frequency.

8. How to maintain ultrasonic cleaners effectively?

1. Continuous working time should not be more than four hours

2. To avoid collision or violent vibration against the machine.

3. Cleaning fluid should be precipitated, filtrated or replaced in time.

4. To keep away from heat-source.

5. To be strictly prohibited the conductive liquid from air intake at the top of the ultrasonic control cabinet.

9. Do the ultrasonic cleaners pass strict testing?

Yes.Every machine passed 48hours continuous cleaning test before exfactory.

10. Does Bakr allow customized new item?

Yes. We have professional R&D team and experienced designing team, so we can help to work out new items as your requirement, ODM is welcome.

11. Large noise for your product?

Ultrasonic noise from professional perspective, mainly by ultrasonic generator vibration of mechanical noise, the ultrasonic is adopt the vibrations frequency of 40000 times per second, noise is unavoidable, but our ultrasonic cleaning machine adopts the sound design, noise control in the range of people can accept.

Customer service

Customer service